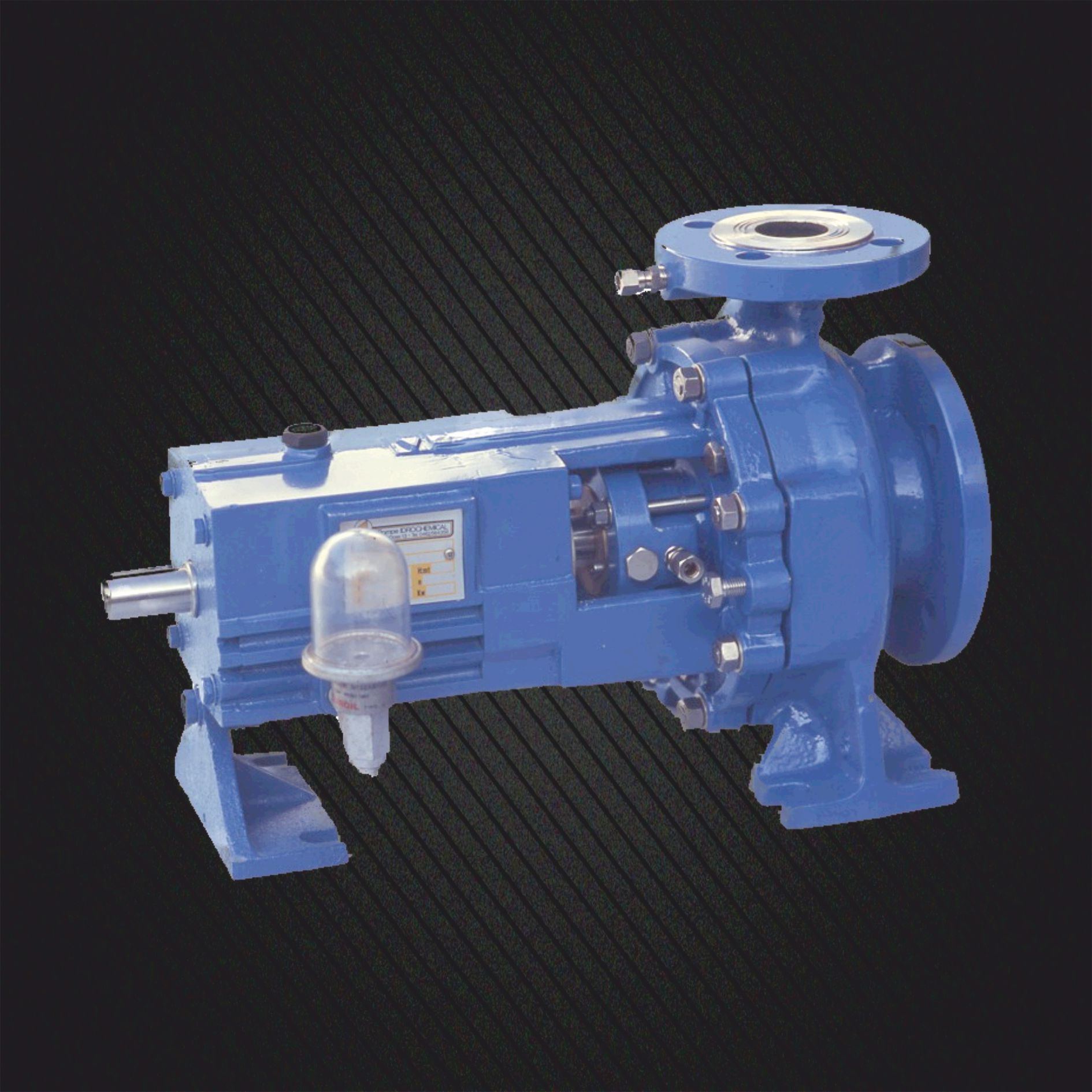

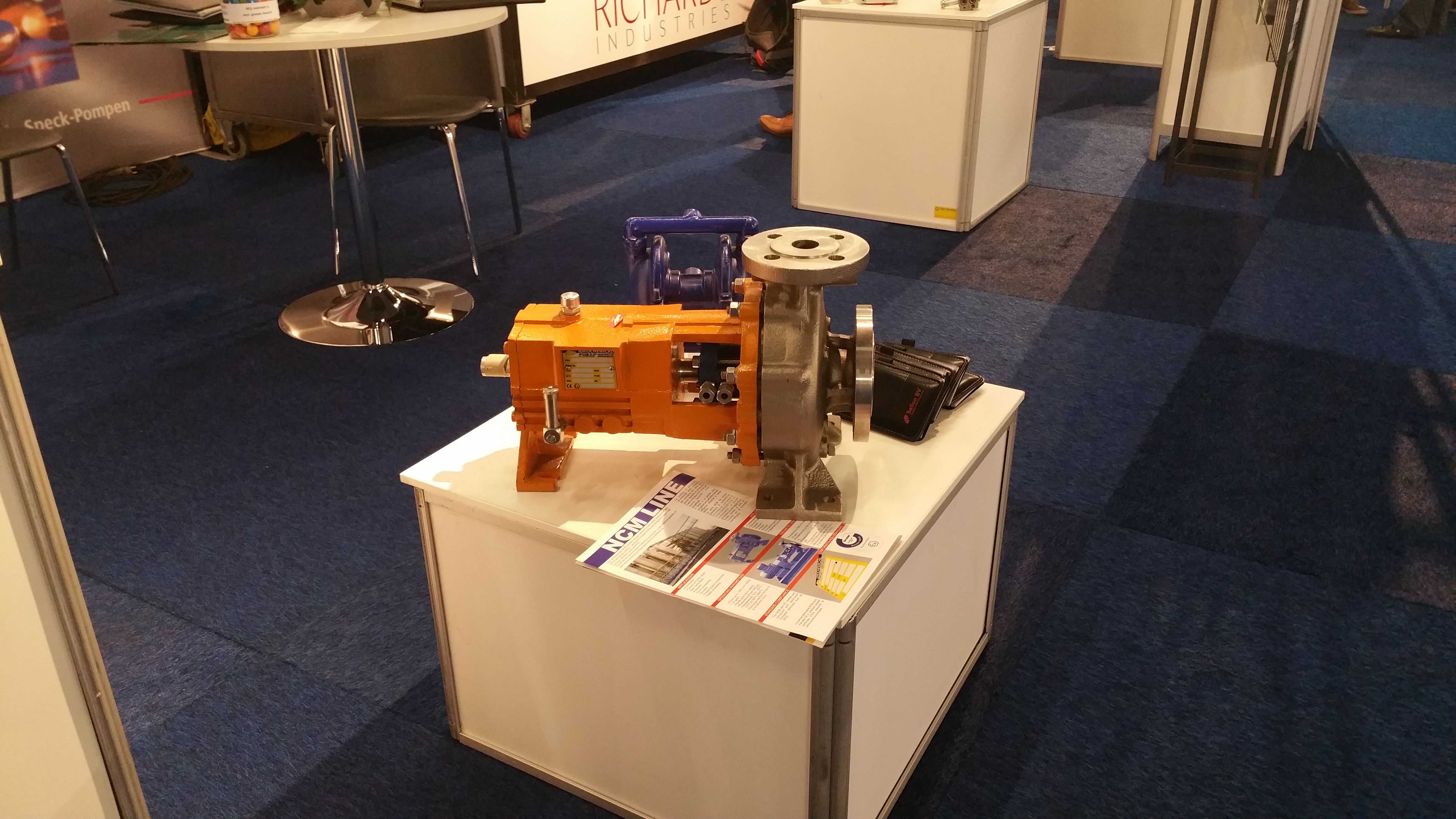

NCM

HORIZONTAL CENTRIFUGAL PUMPS

The Idrochemical NCM process pumps conform to ISO 2858 dimensional and ISO 5199 design criteria. Casing and impeller profiles are designed to reach high hydraulic efficiency and low NPSH.

The NCM line has five sizes of bearing housing with a wide interchangeability of parts allowing the stock of few spare parts for maintenance.

OPERATING PARAMETERS

Flows up to 2500 m3/h (11000 US gpm)

Heads up to 140 m (460 ft)

Pressures to 16 bar (234 psi)

Temperatures from -80°C (-110°F) to 350°C (660°F)

Discharge size from 20 mm (¾ in) to 300mm (12 in)

APPLICATIONS

Acid transfer

Caustic and chlor-alkali

Man made fibers

Polymers

Slurry processing

Solvents

Volatile organic compounds

Waste processing

IMPELLER

Closed with six blades, closed with three blades or open types are available. SCM line with open impeller and wear plate. SCMX line with fully open recessed impeller. Axial thrust balanced with holes or dorsal vanes. Single or double wear ring.

HIGH PRESSURE VERSION

MECHANICAL SEAL

Seal chamber accommodates many seal types including single, double and tandem arrangements. The double and tandem seals are available for more severe and environmentally sensitive applications.

All seals can be backed up by a range of flush plans and auxiliary systems.

Conventional and double cartridge seals can be fitted in accordance with the manufacturer’s standard or with those designed to meet the latest ISO or DIN standards.

External seals and gland packing are optional, as is the seal housing jacket which controls the seal environment.